MIG welding is a process that uses an electrical arc to weld metals together. The process can be used on a variety of materials, including steel, aluminum and copper. To produce a quality weld, you need to use the right type of MIG welding wire.

Welding wire is a very important part of the welding process and there are many different types of welding wire available on the market.

Different types of welding wire are better suited for different applications, so it’s important to know which type of welding wire is right for the job.

In this blog post, we will discuss the different types of MIG welding wire. We will also provide tips for choosing the right type of MIG welding wire for your project. Stay tuned!

types of mIG welding wire

The three main types of wire available for MIG welding are: solid wire, flux cored wire, and metal cored wire.

1. Solid wire

Solid wire is the most common type of welding wire. It is made from a solid piece of metal that is melted and then formed into a wire.

Solid wire is easy to use and produces high-quality welds. However, it can be more expensive than other types of welding wire.

2. Flux cored wire

Flux cored wire is made from a metal core that is surrounded by a flux material. The flux material helps to protect the weld from contamination.

Flux cored wire is less expensive than solid wire, but it can be more difficult to use.

3. Metal cored wire

Metal cored wire is made from a metal core that is surrounded by a metal sheath. The metal sheath helps to protect the weld from contamination. Metal cored wire is more expensive than solid wire, but it can be easier to use.

How do you choose right wire and what factors should you consider?

When choosing a welding wire, you should consider the following factors:

- Material you will be welding

- Thickness of the material

- Type of joint you will be welding

- Position of the weld

- Amount of time you have to weld

If you are welding thin materials, you should use a solid wire. If you are welding thicker materials, you can use flux cored wire or metal cored wire. If you are welding in difficult positions, you should use a metal cored wire.

You should also consider the type of joint you will be welding. If you are welding a butt joint, you can use any type of wire. If you are welding a lap joint, you should use a metal cored wire.

Finally, you should consider the amount of time you have to weld. If you have a lot of time, you can use a solid wire. If you don’t have much time, you should use a metal cored wire.

How do you store welding wire to keep it in good condition?

Welding wire should be stored in a cool, dry place. It should be protected from moisture and heat. Welding wire should also be protected from physical damage.

When handling welding wire, you should wear gloves to protect your hands from cuts and scrapes. You should also avoid touching the welding wire on your skin or clothing.

If you are not using the welding wire right away, you should seal it in an airtight container to keep it fresh for later use.

How do you set up your welder for optimum results with different wires?

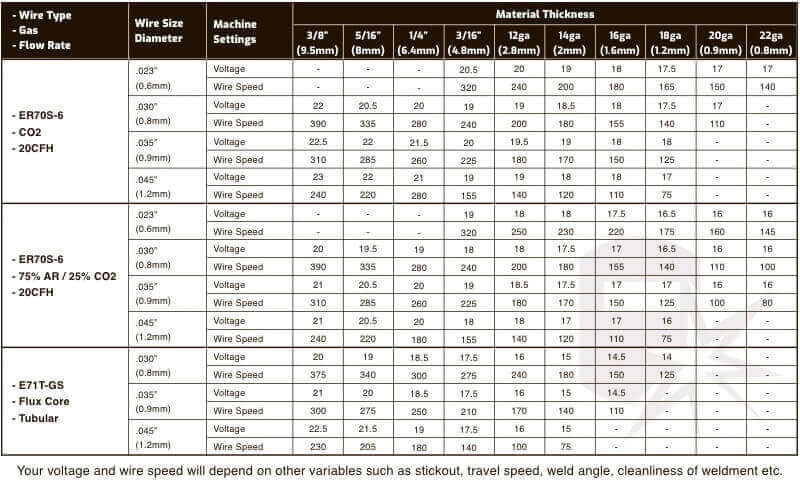

The settings on your welder will depend on the type of welding wire you are using.

- If you are using a solid wire, you should set the amperage between 60 and 80 amps.

- If you are using a flux cored wire, you should set the amperage between 80 and 120 amps.

- If you are using a metal cored wire, you should set the amperage between 120 and 150 amps.

You should also adjust the gas flow rate depending on the type of welding wire you are using.

- If you are using a solid wire, you should set the gas flow rate between 15 and 20 cubic feet per hour.

- If you are using a flux cored wire, you should set the gas flow rate between 20 and 25 cubic feet per hour.

- If you are using a metal cored wire, you should set the gas flow rate between 25 and 35 cubic feet per hour.

What tips can help you get better welds with MIG welding wire?

MIG welding wire is an excellent choice for many projects. It is easy to use and can be found at most hardware stores.

Here are some tips to get the best welds possible:

- Use a clean, dry MIG welding wire. Any contaminants on the wire will affect the quality of your welds.

- When feeding the MIG welding wire, make sure it is straight. If it is not, it can cause problems with the weld.

- Be careful not to overheat the MIG welding wire. If it gets too hot, it can melt and become difficult to work with.

- Use the right gas for your MIG welder. The wrong gas can cause problems with the welds.

- Make sure you have a good ground. This will help to prevent any problems with the welds.

By following these tips, you should be able to get better welds each time you use your Mig welder. If you have any problems, be sure to ask for help from qualified welding professional.

FAQs – mIG welding wire types

What is best wire to use for MIG welding?

The best wire to use for MIG welding is a solid steel wire. This type of wire is less likely to cause problems with your welding machine and will provide a stronger weld than other types of wires.

What do numbers on the MIG wire mean?

The numbers on the MIG wire indicate the wire diameter and the amount of weight per spool. For example, “10 lb.” would be 10 pounds of welding wire. The most common sizes are 11, 12, 13, 14 and 16.

Can all MIG welders use flux core wire?

No, not all MIG welders can use flux core wire. Some MIG welders are designed for use with solid wires only and cannot accommodate the thicker flux core wire.

Additionally, gas-shielded flux core welding generally requires more power than is available from a standard 115V outlet, so you would need a welder that is specifically designed for that purpose.

Wrap Up

As you can see, there are many different types of MIG welding wire available on the market. Whether you need a high-quality weld or are looking for a specific type of wire, there’s sure to be a MIG welding wire that meets your needs.

With so many options to choose from, it can be difficult to know where to start. That’s why we’ve put together this guide – to help you make an informed decision about which wire is best for your needs.

Be sure to consider the properties of each type of MIG welding wire before making your purchase, and ask an expert at your local welding supply store if you have any questions. With the right MIG welding wire, you can create beautiful and durable welds on just about any material.