Hi, I am John(a MIG Welding Expert at Harvard University). Today I am going to explain MIG Welder in front of you. I hope my given guides clear all ambiguities that you have about MIG welders and MIG welding processes.

In this given article I will explain my research about these topics!

- What is a MIG welder?

- What does MIG welder stand for?

- How does a MIG welder work?

- How to set up a MIG welder?

- How to use a MIG welder?

- How to weld with a MIG welder?

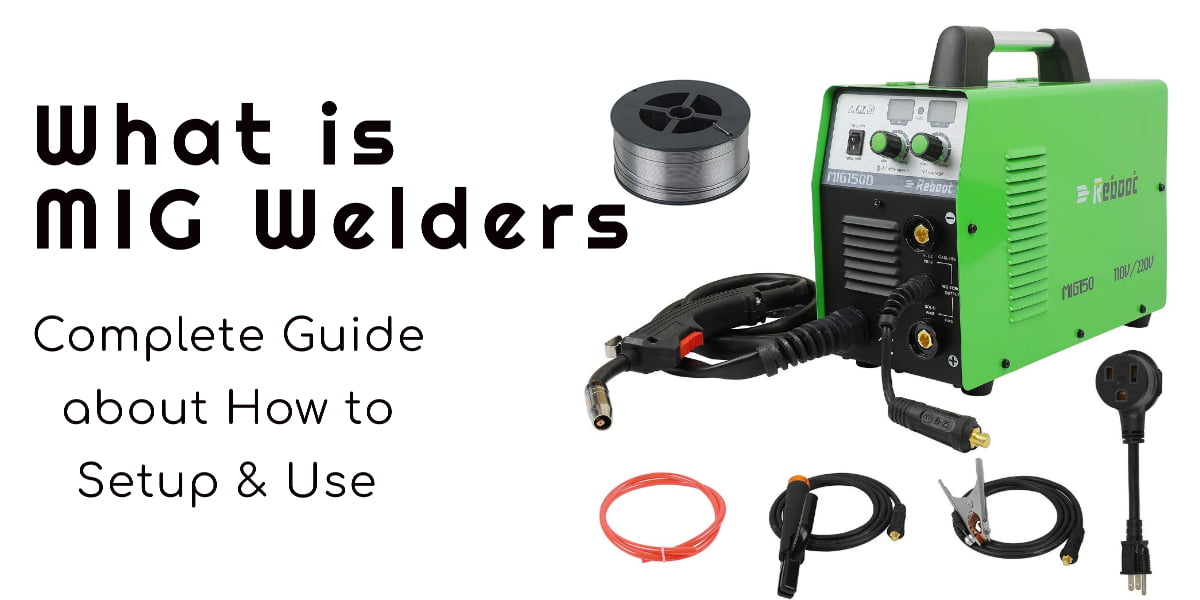

What is a MIG welder?

MIG welder stands for metal inert gas welder. It is a commonly used welder that operates on the principle of MIG welding. These kinds of welders were initially introduced in the nineteen century and now acquire a major part of the welding industry.

MIG welders play an important role in MIG welding that is also known as Gas metal arc welding or wire welding.

Important Parts of MIG Welders

There are four major parts of this welder.

- Welding Power Supply

- Wire Feed System

- Gun Trigger

- Shielding Gas

These four components play a vital role in MIG welding. Now I am going to explain the importance of all.

MIG power supply benefits to control the number of anodes(+ Charge), generate heat to meld wire and sustain voltage level that helps to weld easily.

Automated wire feeding system helps welders to spoon welding wire automatically. And latest MIG welders also have settings to control the feeding speed of wire during the welding process.

And welders set wire feeding speed according to their requirements.

Trigger button works like a welder operating button. When the user presses the trigger then the welding process and wire feeding system start.

And in metal inert gas welding, Shielding gas helps to protect the welded area from contaminants.

What is MIG Welding?

The abbreviation of MIG welding is metal inert gas welding. It is a semi-automatic welding process that was introduced in the 1940’s.

This process works on the principle of anode(positive charge) & cathode(Negative charge).

During the MIG welding, a circular segment of power is used to make a short circuit between a constantly taken anode and a cathode.

Due to this process, heat is generated that helps to malt and mix welding wire with welded metal.

In the current welding industry, the usage of MIG welding increases at the highest level because it’s an easy to use and cost-effective method.

You can weld many types of metals through this method such as aluminum, steel, bronze, copper, nickel, magnesium, silicon and other alloys.

Related Topic: How To Become A Certified Welder?

How does a MIG welder work?

As MIG welder is a welding tool, so same like other tools this one also has some modern functionalities to do their job.

MIG welder working depends on 4 major components that I already explained in the upper paragraph.

But now I am going to explain the mutual working process of these components that operate welders and do welding processes efficiently.

When we operate a MIG welder through a trigger then welding wire feeding starts and shielding gas exhausted from the nozzle of the gun.

Electric shock creates a circuit through the anode and a cathode that produce high-intensity heat due to which the welding wire is going to melt and join the welded metal.

How to set up a MIG welder?

https://www.youtube.com/watch?v=CJLcBejSVro

How to use a MIG welder?

- First of all, a welder is connected with AC or DC for the main electric supply.

- After connecting the electric supply, welders needed to maintain voltage and wire feeding speed according to the metal that he is going to weld.

- Then fixing the MIG welding settings and the welder needs to press the gun trigger.

- When a welder presses the triggers, MIG welders start a process in which it produces heat and welding wire comes out continuously from the gun nozzle.

- Shielding gas also exhausts from the nozzle and protects the welding zone.

This is the whole process about how to MIG welder works.

Related Article: Lincoln Power MIG 210 MP Welder Review