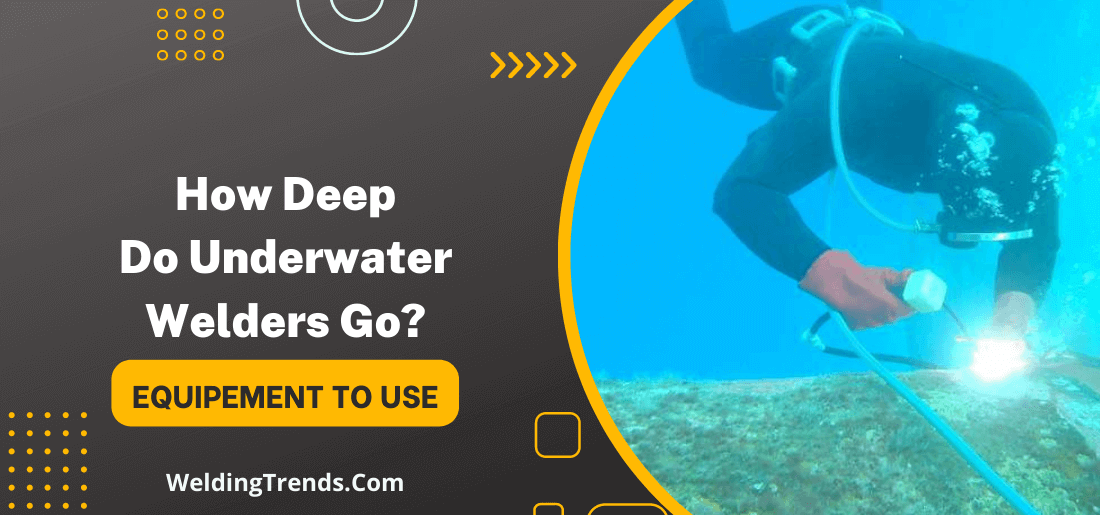

Welders are known for their skills in working with metal. But they have a tough job. Welders who work underwater have to be prepared for a wide variety of challenges. Depths can vary greatly and the welding environment is often unpredictable. To do their job safely and effectively, underwater welders need to be skilled in many different areas.

Here we’ll take a look at some of the things that make underwater welding unique and find out just how deep these welders typically go.

How deep do they have to go to weld underwater?

While the depth at which underwater welders work can vary, it is not uncommon for them to go as deep as 300 feet (91 meters). In some cases, they may even work at depths of 1,000 feet (305 meters) or more.

The type of equipment and techniques used also varies depending on the depth and conditions in which the job is being performed.

In shallower depths, divers may use a surface-supplied diving system where they are connected to an air supply from above water. In deeper depths, they may need to use a mixed gas or saturation diving system to safely work at those pressures and avoid decompression sickness.

Overall, the depth at which an underwater welder works depends on the specific job and diving system being used, but they can reach depths of over 1,000 feet.

Also, safety precautions such as dive plans and emergency procedures are always followed to minimize risk while performing underwater welding tasks.

Working at great depths can be extremely challenging but underwater welders are trained to handle these environments and perform their job effectively.

What are the dangers of welding underwater?

Some of the dangers of welding underwater include:

1) Electrocution or electric shock

While welding underwater, the welder is at a higher risk of being electrocuted due to water being a conductor of electricity.

2) Explosion or fire

The mixture of electricity and water can lead to an explosion, especially in confined spaces like underwater pipelines.

3) Loss of air supply

If proper safety measures are not taken, the welding process can deplete the oxygen supply in the underwater environment and lead to asphyxiation.

4) Drowning

If safety precautions are not followed, a welder may become disoriented or incapacitated while underwater, leading to drowning.

5) Carbon monoxide poisoning

The welding process produces dangerous carbon monoxide gas, which can build up and lead to poisoning in an underwater environment.

6) Hearing damage

The noise produced by welding can lead to permanent hearing damage, especially in enclosed or confined underwater spaces.

7) Eye damage

Welding produces bright flashes of light that can cause temporary or permanent damage to a welder’s eyes.

8) Chemical exposure

Depending on the materials being welded, toxic chemicals can be released into the water and potentially harm marine life or damage the surrounding ecosystem.

9) Equipment malfunction

Equipment used for underwater welding may fail due to corrosion or other issues, leading to injury or even death of the welder.

10) Physical injury

The physical strain of working underwater, combined with the hazards of welding, can lead to injuries such as burns, muscle strains and slips and falls.

Proper safety measures must be followed to mitigate these dangers and ensure the safety of underwater welders.

What type of equipment do underwater welders use?

Underwater welders use a variety of specialized equipment to perform their job safely and effectively. This often includes diving gear such as wetsuits, helmets and air tanks to allow them to work underwater.

They also use welding equipment designed for use in the water, such as underwater cutting torches and flexible power cables. Other equipment that may be used includes lift bags, hand tools and video cameras to inspect the work.

Proper maintenance and care of this equipment are essential to ensure safe and successful underwater welding operations. Overall, underwater welders use a combination of diving gear and welding equipment designed for use in water environments.

They must be trained in the proper use and maintenance of this equipment to minimize risk and perform their job effectively.

FAQs – How deep do underwater welders go?

How long can underwater welders work underwater?

This can vary depending on the specific job and diving system being used, but underwater welders are typically able to work for several hours at a time.

They also undergo decompression procedures after working at great depths to prevent decompression sickness.

Do underwater welders sleep underwater?

No, underwater welders typically do not sleep underwater. They may stay in underwater structures or vessels during their job, but they usually return to the surface to rest and sleep.

Do underwater welders deal with sharks?

This can vary depending on the location of the job. In some cases, underwater welders may encounter sharks and other marine life, but some measures can be taken to avoid or protect against this potential hazard.

Divers may use deterrent devices such as shark shields or complete their work in enclosed areas. Overall, shark encounters are not a common occurrence for underwater welders, but they do have procedures in place to deal with them if necessary.

Is underwater welding stressful?

Underwater welding can be a physically and mentally demanding job, as it requires working in potentially hazardous conditions and using specialized equipment.

However, proper training and safety measures can help alleviate some of this stress. Many underwater welders find the job to be exciting and rewarding.

Overall, the level of stress experienced may vary depending on the individual and the specific job circumstances.

What is a typical day for an underwater welder?

A typical day for an underwater welder may involve the preparation and maintenance of equipment, diving to the work site, performing welding or cutting tasks and completing post-dive procedures.

They may also spend time inspecting and repairing structures or vessels, as well as conducting tests on their work.

Communication with a dive team and other members of the crew is also important to ensure a successful and safe job.

Overall, each day may vary depending on the specific job tasks and location. But in general, underwater welders spend their time diving, welding and completing necessary procedures for their work.

Final Thoughts

So, how deep do underwater welders go? The answer may surprise you. Welders typically work in water that is around 100 feet deep but there have been instances of a welder working at depths of up to 1,000 feet!

With the right training and equipment, underwater welding can be a safe and lucrative career. If you’re interested in becoming an underwater welder, it’s important to find a reputable school with experienced instructors who can teach you everything you need to know about this unique trade.

I hope this article has taught you about the tools and tasks of an underwater welder, as well as what a typical day in their career may look like. Thanks for reading!