Are you concerned about whether the auto-darkening welding helmets are safe for welding or not?

If yes, then we got the right solution. The adverse effect of welding is that it could let you to burn your face, eyes, and skin. Therefore, it is important for you to know how to avoid any severe damage caused due to welding. And that is where an auto-darkening welding helmet comes into play.

Consider you are looking at the spark generated by the weld. Imagine the intensity/heat of the light coming right out of weld sparks and going straight into your eyes and on to your face. It is quite dangerous as this could damage your eyes, leading to permanent vision loss and even damage the eyeball and retina.

Why Is A Welding Helmet Necessary?

A welding helmet, also commonly known as a hood, is essential personal protective equipment during welding process. For a safe working environment, every job requires this product.

For a welder, a helmet is as much important as a welding torch. It is safety equipment that saves the person from the sparks and ultraviolet/infrared light rays. These can cause severe damage to the skin, and in worse cases, it can lead to even vision deficiency. One should keep in mind that the slightest miss care can lead to severe damage.

Welding helmets come in different forms and types, but these helmets’ main aim and purpose are to protect the eyes and face from the sparks that the welding arc generates.

A welding helmet is one of the most visible and safety attire. It gives a welder to add a bit of the personal flair to their welding gear. In this modern era, welding helmets are more functional then they used to be back in the time. A welding helmet should be lightweight and well balanced to worn more comfortably and efficiently.

One should select the right helmet, and while choosing the helmet, one should keep the needed requirements in mind. There are different welding helmets available in the market, but on the basis of modern technology these helmets are categorized into two the following types.

Passive Helmets Protection

Even in this era of modern technology, some welders opt to wear conventional welding helmets. These welding helmets are having a traditional glass lens and fixed shade. The shade is dark at all times.

These welding helmets provide excellent and inexpensive safety precautions but also have their disadvantages. On the safe side, they are still useable protective equipment.

Auto-Darkening Protection

Auto-Darkening helmets are the most advanced type of welding helmets. These helmets have an advantage over passive helmets because they can automatically adjust the shade from an inactive state (light) to the active start (dark) when the arc initiates.

The helmets protect from harmful light emission at all times and darken to shades in milliseconds.

Auto Darkening Welding Helmet Vs Passive Welding Helmet

Auto Darkening Welding Helmet

Auto-darkening welding helmets are the advance types of the welding helmet. They were introduced as the optimum option for welding helmets as they have an auto-switching feature between dark and light shades and are light in weight, and having more comfort. They are more feasible and have more comforting than the other conventional welding helmets.

They have a L.C.D in the lens that makes it easy to switch between dark shade when the spark initiates because of weld and light shade when there is no spark around. Thus it is essential to know how the Auto-darkening helmet works and how it is a more convenient and better option than the passive welding helmets.

The design is to ease further and ensure the protection of the welder. With the constant taking on and off the helmet due to the checking and ensuring of the weldment, it was a quite disastrous and hectic job to wear a passive helmet. Thus to this solution, an auto-darkening welding helmet was developed.

Passive Helmets

Passive helmets have a traditional glass lens and have only a single shade. These are old fashioned helmets that do not allow the changing shade factor, which is a disastrous thing for eyes. Because the welder keeps seeing through the same shade for a long time, this causes the eyes to adapt to the mono shade, hindering welder vision when he takes off the helmet.

Passive helmets are better than not having any protection. As these do ensure that you don’t get hurt by the spark, it saves the welder’s skin and eyes that the weld’s spark can seriously damage. Hence these helmets are of great use if your aim is to weld for a short time or the welding specimen is short.

Although passive helmets are an excellent option to weld, it has its adverse effects. The welder needs to lift the helmet while welding to see the weldment, reset the weld and see whether the weld is according to the desired use or not. This lifting of the helmet can cause severe pain in the neck. It adversely affects the neck and causes some unbearable pain. It is essential not to consider these helmets in such circumstances where your workload is high and painful.

How Does Auto-Darkening Helmets works to Ensure Safety?

Once the auto-darkening helmet observes that the arc has initiated, and then it automatically adjusts the shade from an inactive state (light) to an active state (dark). This ability of the auto-darkening helmet gives it an extra advantage. It saves the skin and protects the vision from being getting affected. It is the far most effective helmet for welders.

In modern helmets, photovoltaic cell installation in the helmets enables you to work without switching between shades. The helmets operate on their own in the presence of sunlight. More than that, batteries are also installed that let you work with the uninterrupted power supply to the helmet.

You can also add on additional batteries to make your helmet work more effectively and efficiently. It will affect your auto-darkening welding-helmet performance as this will increase your helmet’s power capacity and ensure that proper and desiring power delivers to the helmet.

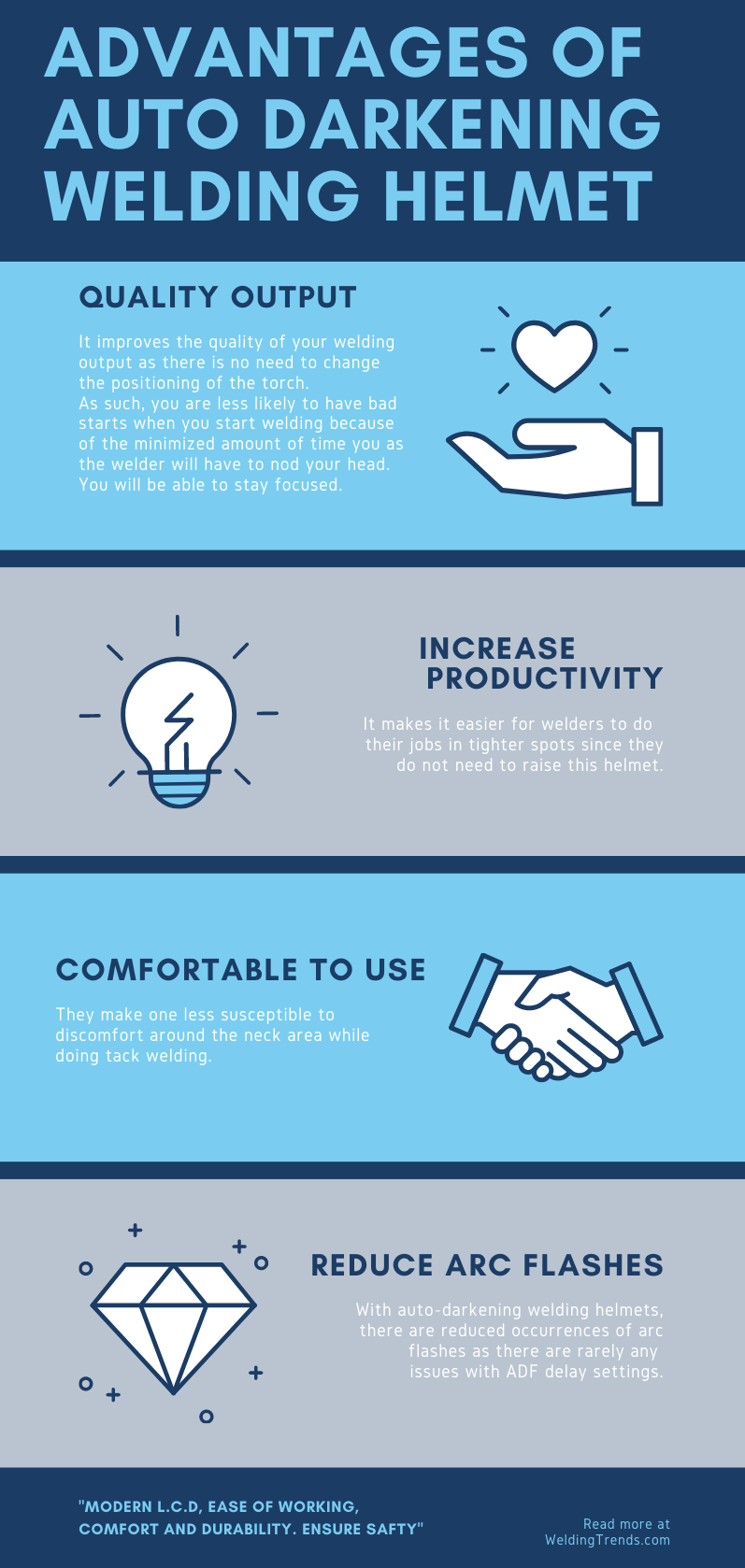

Advantages of Auto Darkening Welding Helmets

An auto-darkening welding helmet is far much better to consider for welding. It is essential to consider the auto-darkening helmet as the priority because passive helmets make the welder job laggy. The auto-darkening welding helmet has an auto shade shifting feature that gives it an advantage over passive welding helmets. It is one of the significant advantages.

Some of the advantages of auto darkening welding helmets as compare to passive helmets are discuss below,

Modern L.C.D

Auto-darkening helmets are considerably better than passive helmets in many ways. These are advanced in the sense that light in weight, having modern equipment, more durability, and less weight. Its working is relatively easy as it has an L.C.D that has the ability to change its shade automatically.

Ease Of Working

Besides, in the passive welding helmets, the helmet’s lid is to be removed each time so the welder can see the weldment. It causes the job to become unproductive. One should keep in mind that with the auto-darkening helmet, you don’t have to do this. The sensing capabilities of the auto darkening welding helmet are pretty astonishing.

Workload

It is also essential to consider that the workload depends on the amount of weld you will do. So if you are working privately, then the passive helmet is the right choice for you, but if you are on a contract with a company, it is better to opt for an Auto-darkening welding helmet would be paying for it.

Comfort and Durability

Another critical feature involves less weight, more durability and more comfort. We also see that whenever a new technology or advancement comes as the previous one’s successor, it makes the last method obsolete. Luckily in this protective equipment, the auto-darkening welding helmets were not wholly replaced and are still in use in a much higher context.

Consideration When Purchasing An Auto Darkening Welding Helmet?

Deep analyses and points are needed to consider when purchasing an auto-darkening welding helmet to select which helmet to choose and which not. One should consider the weld requirements that he requires to take into account. Considering things like the helmet’s weight, the helmet’s usage, and space necessity are genuine concerns discussed below:

Safety of Eyes and skin

Safety is the most important thing to consider why you are looking for an auto-darkening helmet because welding without any proper protection can severely damage your eyes and waste your time, affecting welder productivity. It needs to be taken into account to ensure that the welder eyes and skin are safe from the spark and the spark does not reach the welder skin. It can lead to severe damage to the skin, such as burns.

Considering the Budget

While buying an auto-darkening helmet, budget is another very important factor to consider. If your work is less hectic and does not require welding to a great extent, it is better to opt for a passive helmet. But if your job is relatively inflexible and requires welding for a long time, it is better to go for the auto-darkening welding helmet.

Auto Darkening Helmet Care And Maintenance

It is essential to take good care of the auto-darkening welding helmets. One should consider that maintenance and care can lead to the better and effective working of the auto-darkening welding helmet. The proper maintenance of these helmets can lead to a stable and effectively good weld joint. Thus taking care and doing maintenance of the auto-darkening welding helmet is essential.

Since welders work in challenging and humid conditions, they have high exposure to the weld fumes that can impact the welding helmet’s service life that acts as the shield against weld. Regular care and maintenance are needed to schedule making your auto-darkening welding helmet work properly.

The most vulnerable thing to the helmet is the lens of the helmet. One needs to change the helmet when it becomes a bit of damage and starts to have pits. It will provide a better vision for the welder. It will ensure good quality weld and ensure that productivity is increase. It will save you a lot of time.

Are Solar-Powered Auto Darkening Welding Helmets A Good Choice?

Before concluding whether a solar-powered auto-darkening welding helmet is a good choice or not, one should understand its functionality. The solar-powered auto-darkening welding helmet uses a photovoltaic cell placed on top of the helmets that captures the sunlight and transforms it into their power source.

The battery is also essential in addition to the photovoltaic cells. These cells ensure that the proper power is delivered to the helmet so that it operates properly. These helmets are coming to the market with an automatic on/off switchthat automatically eases power deliverance usage rather than a conventional one that uses a control.

These are not suitable choices as if the welder is working at night; then, it will operate until the batteries drain out of energy up to a specific limit. Also, suppose the welder is operating inside where there is no direct sunlight. In that case, the helmet will automatically switch to the batteries that will affect the solar-powered auto-darkening welding helmets’ performance.

You Can Use Solar-Powered Helmets Inside And Outside

Solar-powered helmets can be used outdoors in the sunlight easily without much interruption. It is causing severe issues if used inside where there is no direct sunlight. It will hinder the performance of the helmet. It can lead to vision loss from the helmet and create improper weld and weld of poor quality.

Thus batteries are used in the solar power system. It ensures that the helmet does not lose power outside and inside. Batteries use to avoid the power deficit that solar energy cannot full fill. Since solar panels installed on the helmet cannot create sufficient power, especially on the welding helmet, there is a limited number of solar panels.

The solar panels are the photovoltaic cells that generate electricity from the sunlight rays. One should keep in mind that these photovoltaic cells generate a little energy that has variable voltages. One needs a battery to store its power and to maintain the constant voltage. For this reason, batteries are also essential.

Did you know Latest Trends in Welding Industry