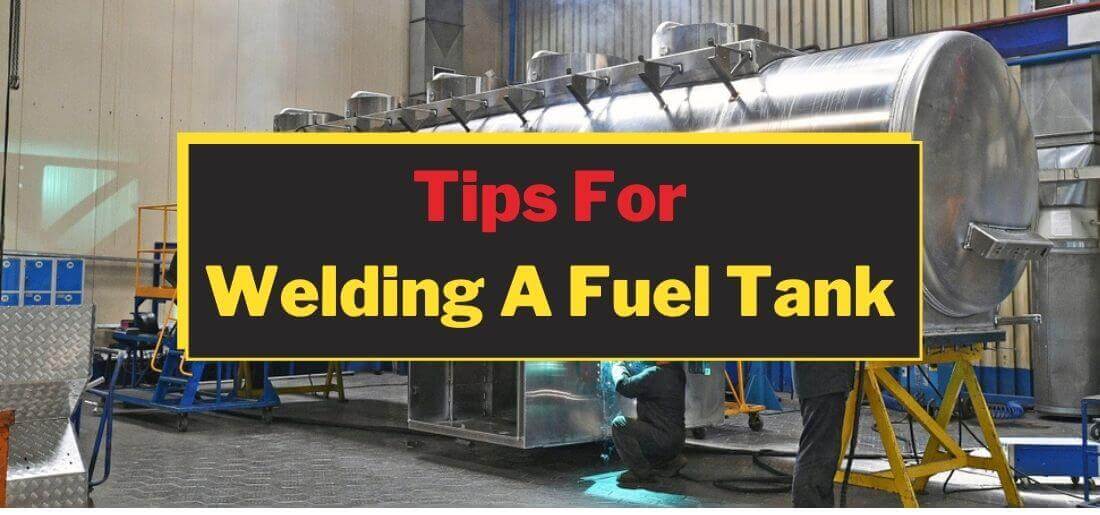

Are you looking for a bundle of information and tips to weld your own fuel tank?

If yes, then we are here to help you out. It seems a very easy and inexpensive process to weld a fuel tank. However, many elements should be considered in the welding fuel tank with residual oil, diesel, or petrol dangerous.

A welding fuel tank is a procedure of sealing a crack on the tank’s surface via heating the metal to rebinds together. As a result, it will form a robust joint that will no longer permit gasoline to escape.

The high temperature and response taking vicinity at some point of this welding process; however, it is quite unpredictable. To control a welding fuel tank’s reactivity, you can fully empty a tank and smooth it out before filling it with a noble gas. In this article, we will discuss almost all the aspects of welding a fuel tank. Please give it a read and gather information about welding the fuel tank.

Why Welding A Fuel Tank Is Dangerous?

Welding a fuel tank might be a hazardous process. The reason is that irrespective of liquids, the fuel gases can cause an explosion to any spark. Moreover, the extra oxygen trapped in patrol is also a leading cause to make the welding procedure dangerous.

So, it is hazardous when it comes to weld a fuel tank. To make the welding process more manageable, you have to remove all the excess fuel gases from the tank and clean it properly. But the cleaning process of a fuel tank is itself risky. That’s why, most of the time, the welding fuel tank is a dangerous and explosive process.

how to clean a fuel tank before welding?

Cleaning a fuel tank is the very first step in the welding process. Before starting welding, you have to make sure that the tank is all empty and no residual gas or patrol is left behind. Otherwise, the chances of the explosion increase up to many times. You can say that the welding process is based on the cleaning of the fuel tank.

First of all, to clean a fuel tank, you have to remove all the residual gases out. Make sure that even a single molecule of gas is not present inside the fuel tank. For this purpose, you can fill argon gas into the tank. Being a noble gas, argon doesn’t react and can stop or check the reaction.

The other way is to put ice into the tank that lowers the residual material’s temperature in the tank. In this way, the chances of the explosion are significantly less. So, you can safely clean a fuel tank before welding by using any of the up-mentioned techniques.

What Causes A Hole In A Fuel Tank?

A hole in a fuel tank means the constant leakage of fuel or gas from your vehicle. Moreover, it can be extremely dangerous. Leakage is not acceptable anyways. It would be best for you to find out the leading causes of fuel and avoid them.

The leading cause of a hole in a fuel tank is due to the constant rubbing of the surface to any harsh thing that causes the hole. Moreover, carrying it through the uneven or rocky surface also cause a hole in the fuel tank. This causes leakage of the fuel from the hole, which results in the loss of fuel and very dangerous. So, it is of utmost importance to take precautions regarding a hole in a fuel tank.

How Much Does It Cost To Fix A Hole In A Fuel Tank?

The process of fixing a hole requires a lot of care. If you locate a hole in a fuel tank and want to fix it, you have to clean it properly because even a single particle of residual gas in the tank can give you a tough time and cause an explosion.

The rough estimate about the cost of fixing a hole in a fuel tank is about $50 or above. Mostly, the hole in a fuel tank is a signal to change your fuel tank. So, most people prefer to change the fuel tank instead of getting it fixed.

Can You Use JB Weld-On A Fuel Tank?

Mostly, people are confused about using JB weld for repairing their fuel tank. The answer is yes. You can easily use JB weld for welding fuel tank holes. This is the fastest and easiest way to repair a hole in a fuel tank.

To repair a hole in your fuel tank, firstly, you will have to locate the hole in your tank. After finding the hole, clean it properly. Starting from its surface, make sure to clean it around the hole and the nearby space with utmost care. Also, make sure that no dirt or residual gas is stuck in the concerned area.

Now, take the Steal Stick and knead it nicely. After kneading it, it will be a sticky putty. Apply this putty on the hole. Although, you don’t have to apply putty on the whole fuel tank. But make sure that the hole and space around it are covered properly to provide complete protection.

Can You Use Flex Seal On A Fuel Tank?

Using a flex seal to repair a hole in a fuel tank is not encouraged at all. Flex seal is good enough for plastic material. But as far as the gas fuel tank concerns, the flex seal is not recommended at all.

Flex seal is not used for fuel tanks because it contains any flammable liquid or gas. It is very risky and can cause an explosion. Therefore, you should choose another option to fix a hole in your fuel tank instead of a flex seal.

Best Practices To Safely Weld A Fuel Tank:

Welding is a matter of utmost care and attention. If you want to weld something, you must ensure the necessary protocols and precautions for making the process safe and successful. If you’re going to weld a fuel tank, you must follow all the safety measures more concisely and properly.

- Before welding a fuel tank, make sure that you have cleaned it properly.

- Even a small amount of residual gas can cause a big explosion. So, learn all the best methods to clean it.

- For disposing of the residual gases, make sure that the place is ventilated. The argon gas that we use to remove residual gases from the tank may cause suffocation. So, to avoid any accident, make sure to choose a ventilated area to dispose of the residual gases.

- Ensure that the tools and equipment you use to remove the ample residual gases are safe and designed specifically for this purpose.

- It would be best to use goggles, gloves, a helmet, and all precautions to make yourself safe and sound.

Practical Tips For Welding On A Fuel Tank:

We provide you a complete set of precautions and safety measures that you should follow to weld a fuel tank safely. These precautions are given below:

- You must follow all the protocols to ensure personal safety.

- Use heat-resistant goggles, gloves, and helmets.

- Always use leather jackets while welding. Heat and pressure controlling gadgets must be used while welding a fuel tank.

- Removing the residual gas is a must-do during welding fuel tank.

Is It Safe To Weld A Diesel Fuel Tank?

It is frequently asked by people that is it safe to weld a diesel fuel tank? Welding a diesel fuel tank can be extremely dangerous and expensive. If you use the MIG process, you can be the victim of argon gas suffocation. Moreover, the chances of the explosion are always there. Therefore, it is not safe to weld a diesel fuel tank.

Hence, the answer to the question ‘is it safe to weld a diesel fuel tank?’ is simply no.

Is It Safe To Drill A Hole In A Fuel Tank?

Yes, it is safe to drill a hole in a fuel tank. Moreover, it is quite easy to drill a hole for mechanics, but when we come up with an empty fuel tank with almost zero fuel, it causes drying out of parts and seizing things. In that case, it is scary and dangerous to drill a hole. It is clear that an empty one is devastated so, the safest way is to fill it with water while drilling it.

Therefore, first, you have to clean it before drilling properly. After cleaning it, fill it with water, drill a hole in it. After the drill, drain water out of it, and you have done a drill in a fuel tank safely.

Conclusion:

Hence, it is clear from the article that welding a hole in a fuel tank is not safe. It can be very dangerous and expensive. To avoid any mishap, you must follow all the instructions, such as cleaning the whole area before welding.

Personal safety measures are also crucial to a fellow, including wearing goggles, leather jackets, helmets, and heat-resistant gloves. All these measures will make your welding process safe and easy. Now, you can weld your fuel tank without any worry.