Yes, you can weld stainless steel with normal MIG wire. However, there are some things you need to consider before welding stainless steel.

Welding stainless steel can be a challenge, but it is possible with the right equipment and techniques. In order to weld stainless steel successfully, you need to use a MIG wire that is specifically designed for welding this type of metal.

However, if you don’t have access to the right MIG wire, it is possible to weld stainless steel using normal MIG wire. Just make sure you adjust your settings accordingly.

So, whether you’re a beginner or an experienced welder, read on to learn everything you need to know about welding stainless steel!

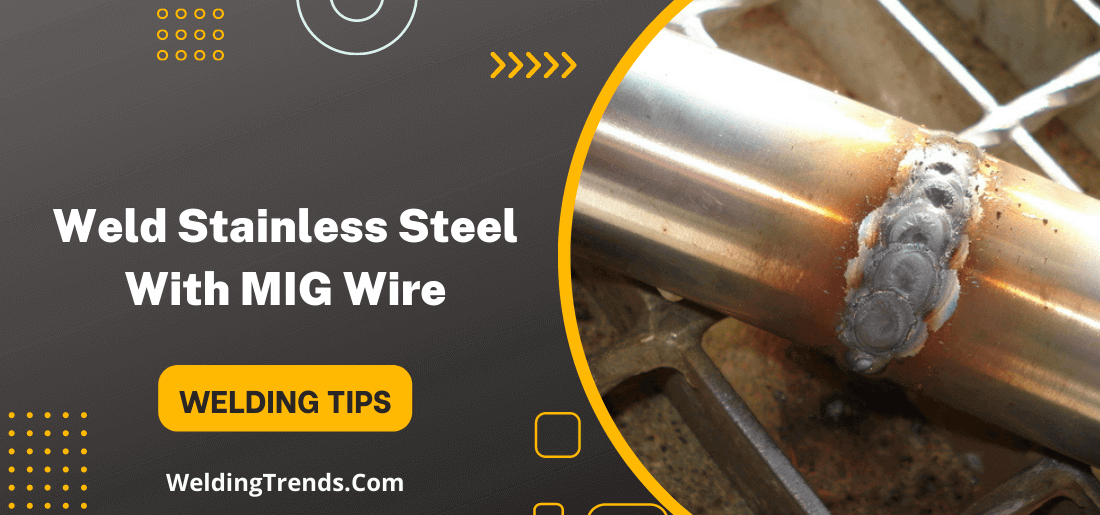

weld stainless steel with normal MIG wire

The short answer is yes, you can weld stainless steel with a regular MIG welder. However, there are some things that you need to keep in mind when welding stainless steel, such as using the right type of wire and gas.

Type of wire

Regular MIG wire is made of mild steel, which is not ideal for welding stainless steel. The reason for this is that mild steel wire will not produce a strong enough weld on stainless steel. Additionally, mild steel wire will cause the formation of rust on your welds.

To avoid these issues, it’s important to use a type of wire that is specifically designed for welding stainless steel. This type of wire is typically made of austenitic stainless steel, which is much more resistant to corrosion. Additionally, austenitic stainless steel wire will produce a stronger weld on stainless steel.

Type of Gas

When welding stainless steel, it’s also important to use the right type of gas. Argon gas is typically used when welding stainless steel, as it provides the best results. However, you can also use CO2 gas if you’re looking for a less expensive option.

Just keep in mind that using CO2 gas will result in a slightly lower quality weld.

Different types of MIG welding wire available for welding stainless steel

There are several types of MIG welding wire available for welding stainless steel. These include:

- ER309L: This wire is used for welding base metals of similar composition, including 304 and 304L stainless steels.

- ER308L: This wire is used for welding base metals of similar composition, including 302 and 304 stainless steels.

- ER316L: This wire is used for welding base metals of similar composition, including 316 and 316L stainless steels.

- ER347: This wire is used for welding base metals of similar composition, including 321 and 347 stainless steels.

- Inconel 625: This wire is used for welding Inconel alloys including 601, 625, 718, and X-750.

- Hastelloy C276: This wire is used for welding Hastelloy alloys including C276, C22, and B-2.

- Titanium: This wire is used for welding titanium alloys including 6Al-4V and 8Al-4V.

- Aluminum: This wire is used for welding aluminum alloys including 5052, 5356, and 4043.

- Cobalt: This wire is used for welding cobalt alloys including Stellite 6 and Haynes 25.

Different grades of MIG stainless steel welding wire are available depending on the intended use. For example, ER309L is often used for general purpose applications while ER308L is best suited for welding 304 and 304L stainless steels.

How to set up your welder and torch for MIG welding stainless steel?

First, you need to set your welder to the proper settings. The recommended settings are as follows:

- Wire Size: .035 inches

- Gas Type: Argon/CO2 Mix ( shielding gas)

- Wire Feed Speed: Slow

- Voltage: 18-20 volts AC

- Next, you need to adjust your torch. The recommended torch settings are as follows:

- Gas Flow Rate: 15-20 CFH

- Tip Size: .030-.035 inches

- Nozzle Size: 5P (or size that is one size larger than your contact tip)

- The angle of Hold: 10-15 degrees from vertical

Now you are ready to MIG weld stainless steel!

Keep in mind that when welding stainless steel, it is important to use a push technique rather than a pull technique. This will help prevent the warping of the metal. Also, be sure to use short, consistent weld passes.

If you need to make longer weld passes, be sure to stop periodically and let the metal cool before continuing. Overheating the metal can cause warping as well.

Now that you know how to set up your welder and torch for MIG welding stainless steel, get out there and give it a try!

Stainless steel is a great material to work with and can be used for a variety of projects. With a little practice, you’ll be welding like a pro in no time!

Tips For Welding Stainless Steel with MIG?

Following are the important tips that can help you to weld stainless steel with MIG:

1) Use right Gas

Use a shielding gas that is specifically designed for welding stainless steel. Argon-based mixtures or 100% argon are often used. Helium can also be used in some cases.

2) Use Right wire

Use a stainless steel wire that is classified as ER308L or ER309L. These wires are specifically designed for welding austenitic alloys such as 304 and 309 stainless steels.

3) Set Material Parameters

Adjust the welding parameters according to the thickness of the material being welded. For thin materials, lower heat input and higher travel speeds are typically used. For thick materials, higher heat input and lower travel speeds may be necessary.

4) Use Tungsten Electrode

Use a tungsten electrode that is compatible with the shielding gas being used. In most cases, a 2% thoriated tungsten electrode should be used.

5) Proper Welding Technique

Use the proper welding technique. When welding thin materials, it is important to use a technique that minimizes heat input and distortion. One such technique is known as pulse welding.

When welding thick materials, it is important to use a technique that allows for proper penetration while minimizing the risk of burn-through. One such technique is known as stringer bead welding.

6) Clean Material before Weld

Be sure to clean the stainless steel before welding. Any contaminants on the surface of the material can cause problems with weld quality and corrosion resistance. The best way to clean stainless steel is to use a mild abrasive cleaner followed by a thorough rinse with clean water.

Examples of projects that can be completed with MIG welding stainless steel

The projects that can be completed with MIG welding stainless steel are vast and varied. Some examples include:

- Creating custom stainless steel countertops

- Welding together stainless steel piping to create customized plumbing systems

- Building a stainless steel enclosure for sensitive equipment

- Constructing a custom grill or barbecue

- Making repairs to existing stainless steel structures

- Building a custom exhaust system for a vehicle

- Creating a one-of-a-kind piece of art or sculpture

The possibilities are nearly endless when it comes to MIG welding stainless steel. With the right tools and know-how, almost any project can be completed successfully. So get creative and see what you can come up with!

FAQs – weld stainless steel with normal MIG wire

Can you weld stainless with a regular MIG welder?

No, you cannot weld stainless with a regular MIG welder. Stainless steel has a higher melting point than regular steel, so you need a special welder that is designed for stainless steel. Otherwise, you will not be able to properly weld the two materials together.

Can you weld stainless with mild wire?

Yes, you can weld stainless steel with mild wire, but it is not recommended. The main reason for this is that stainless steel is more difficult to weld than mild steel, so using a less powerful welding machine can make the process more difficult.

Additionally, the risk of contamination is higher when welding stainless steel, so using a mild wire may result in a less than ideal weld.

What gas do you use for stainless steel MIG welding?

The gas you use for stainless steel MIG welding depends on the type of stainless steel you are using. For most grades of stainless steel, you will need to use an argon and carbon dioxide mix. However, for some higher grades of stainless steel, you may need to use 100% pure argon.

You should always consult your welder’s manual or the stainless steel manufacturer to determine the best gas for your particular application.

What kind of MIG wire do you use for stainless steel?

There are a few different types of MIG wire that can be used for welding stainless steel, including 308L, 309L, and 316L wires. While other types of wire can technically be used, these three are the most common and will provide the best results.

Each type of wire is designed for a specific purpose, so it’s important to choose the right one for your project.

Wrap Up

Yes, you can weld stainless steel with normal MIG wire. There are a few reasons why you might want to do this.

- First, it’s cheaper than buying stainless steel welding wire.

- Second, it’s more readily available.

- And finally, it works just as well for welding thin sheets of stainless steel as regular welding wire does.

So if you need to weld some stainless steel and don’t have any welding wire on hand, don’t panic – just use some regular MIG wire and you’ll be good to go!