Welding is a process that involves melting two pieces of metal together. This can be done with a variety of methods, including gas welding, arc welding and spot welding.

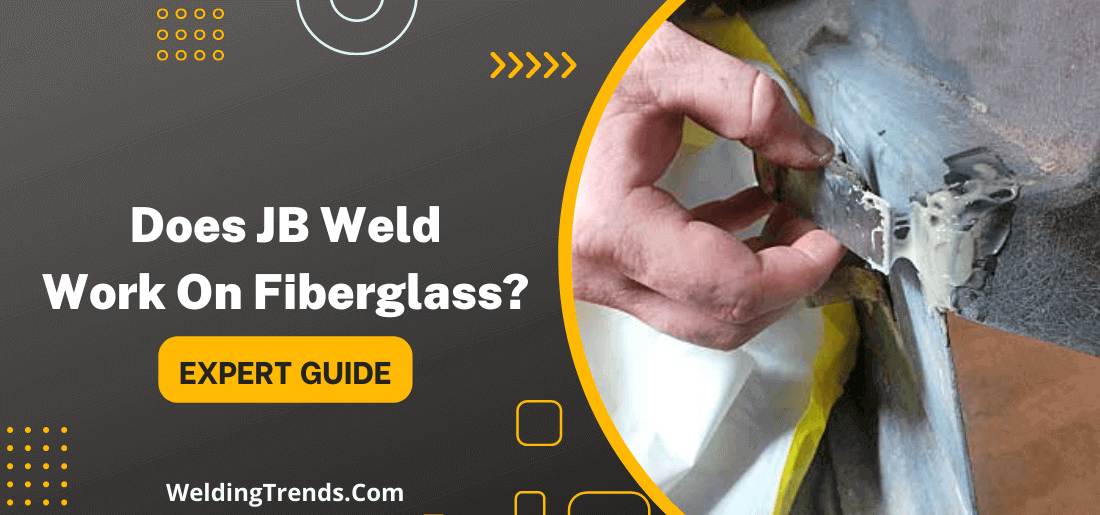

JB weld is a specific type of weld that is made from epoxy resin and hardener. It is often used to repair plastic, fiberglass and metal objects.

In this blog post, we will explore the question: does JB weld work on fiberglass? And find out if it’s the best adhesive for repairing fiberglass items.

Does JB weld work on fiberglass repairs?

Yes, JB weld can be used for fiberglass repairs. However, it is important to follow the instructions carefully and make sure that the surfaces are clean and dry before applying the weld.

If done correctly, the weld will be strong and permanent. However, if not done correctly, the weld may not hold and could cause further damage to the fiberglass.

However, it is not the best adhesive for this purpose. The reason for this is that JB weld is not as flexible as other adhesives and it does not bond as well to fiberglass as it does to metal.

If you are looking for the best adhesive for repairing fiberglass, we recommend using a two-part epoxy resin. This type of adhesive is more flexible and bonds better to fiberglass than JB weld.

Related Topic: Does JB Weld Work On Stainless Steel?

benefits of using JB weld for fiberglass repair projects

Following are the benefits of using JB welds for fiberglass repair projects:

- It can be used to repair cracks, holes and leaks in fiberglass surfaces.

- It can also be used to bond two pieces of fiberglass together.

- JB weld is a strong and durable adhesive that will create a lasting repair.

- It is easy to use and does not require any special tools or equipment.

- JB weld can be used on both interior and exterior surfaces.

- It is available in a variety of colors to match the surrounding area.

- JB weld is affordable, safe to use and does not emit any harmful fumes.

- It is also non-flammable and will not ignite if exposed to heat or flame.

- JB weld can be sanded, painted and drilled once it has cured.

drawbacks of using JB weld for fiberglass repair projects

The potential drawback of using JB welds for fiberglass repair projects are:

- It is not as strong as other epoxy resins

- It is not as flexible as other epoxy resins, so it can crack and break easily

- It is not as resistant to heat and chemicals as other epoxy resins.

- JB weld can be difficult to work with and it doesn’t always adhere well to fiberglass

- If you’re not careful, it can also make your repair project look messy and amateurish.

tips for using JB weld to fix fiberglass damage?

- Choose the right JB weld product for your repair. There are a variety of JB weld products available, so make sure to select the one that is best suited for your particular repair.

- Clean and prep the area to be repaired. This step is critical in ensuring that the JB weld will adhere properly.

- Mix the JB weld according to the instructions. Be sure to mix it thoroughly in order to get the best results.

- Apply the JB weld to the damaged area and allow it to cure according to the instructions. Once it is fully cured, your repair should be strong and durable.

By conscientiously following these steps, you can ensure that your JB weld repair will be successful.

When is it best to use JB weld to fix fiberglass damage and when is it not recommended?

JB weld is not recommended for use on fiberglass damage that is located in an area that will experience a lot of stress or movement, as the bond created by the JB weld may not be strong enough to hold up under these conditions.

However, JB weld can be used to fix smaller, less severe damage to fiber glasses, such as cracks or chips. When using JB weld on fiberglass, it is important to make sure that the surface is clean and free of dirt or debris before applying the welding compound.

Also Read: Is JB Weld Food Safe?

some other ways to fix fiberglass damage without using a JB weld?

Some other ways to fix fiberglass damage include:

1) Epoxy resin

Epoxy resin is often used for repairing cracks and holes in fiberglass, as it provides a strong bond and can be sanded and painted once it has cured.

2) Polyester resin

Polyester resin is another option for repairing damage to fiberglass and is typically used in conjunction with a fiberglass mat or cloth.

3) Gelcoat

Gelcoat is a type of resin that is often used as a topcoat on fiberglass and can also be used to repair cracks and holes.

4) Bondo

Bondo is a putty-like material that can be used to fill in cracks and holes in fiberglass and can then be sanded and painted.

5) Duct tape

Duct tape can be used as a temporary fix for small holes and cracks in fiberglass and can also be used to hold pieces of fiberglass in place while epoxy or resin is curing.

6) Fiberglass tape

Fiberglass tape is an effective way to repair small holes and cracks in fiberglass surfaces and is also useful for reinforcing damaged areas.

7) Patch kit

Many commercially available patch kits can be used to repair damage to the fiberglass. These typically include a resin or epoxy, as well as some type of fiberglass mat or cloth.

8) Spray foam

Spray foam can be used to fill in cracks and holes in fiberglass and can also be used to provide extra support for damaged areas.

FAQs – jB weld on fiberglass

What is best glue to use on fiberglass?

There are a few different types of glue that can be used on fiberglass, but the best type to use is epoxy. Epoxy is a strong adhesive that will create a permanent bond between the two surfaces.

It is important to make sure that the surfaces are clean. Once the epoxy has been applied, it will need to be allowed to cure for 24 hours before it is fully set.

If you are looking for a less permanent option, then cyanoacrylate (CA) glue can be used. CA glue is also very strong, but it can be dissolved with acetone if necessary.

Can epoxy be used on fiberglass?

Yes, epoxy can be used on fiberglass. It is often used as an adhesive to bond fiberglass to other materials. Epoxy is also used to coat and protect fiberglass from damage.

Does Gorilla Glue work on fiberglass?

Gorilla Glue is a great product for bonding fiberglass, but it is important to follow the instructions carefully.

For best results, roughen the surfaces to be glued with sandpaper and clean them with acetone or alcohol before applying the Gorilla Glue. Allow the glue to cure for 24 hours before subjecting the bond to stress.

Which is stronger epoxy or J-B Weld?

Epoxy is stronger than J-B Weld. Epoxy is a two-part adhesive that is heat resistant and bonds well to metal, glass and plastic. J-B Weld is a two-part epoxy that dries to a dark gray color and can be used on wood, metal, ceramic, glass and more.

Related Article: Is JB Weld Gas Resistant?

Summary

JB weld is a great adhesive to use on fiberglass because it bonds well and creates a strong seal.

Fiberglass can be repaired with JB weld by using the same process as you would use to fix metal surfaces. JB weld can also be used to create custom fiberglass pieces, such as boat hulls or car parts. So there you have it – our guide on how to use JB weld on fiberglass!

Remember that this adhesive works best when bonding two clean and rough surfaces together, so take care to prepare your work area properly before getting started.